When shopping for new flooring, it is essential to work with stores that know the products they’re selling and properly pair you with the best-suited floor for your application, budget, appearance, and, most importantly, the maintenance requirements. Prefinished engineered hardwood flooring is suitable for those areas where solid flooring is not appropriate.

The Benefits of Water-Based Polyurethane in Wood Floor Finishing

When it comes to choosing a finish for wood floors, water-based polyurethane is a standout option due to its eco-friendliness and ability to enhance the quality of the wood. This type of finish is known for its durability and ability to protect against wear, tear, and moisture damage. Unlike traditional finishes, water-based polyurethane has lower emission levels, making it a more sustainable choice. Additionally, it dries quickly, allowing for multiple coats to be applied in a single day, which speeds up the finishing process. It also offers the flexibility of a glossy or matte appearance.

One significant advantage of water-based polyurethane is its low odor, which is especially beneficial for indoor applications. The fast drying time not only makes the application process quicker but also reduces the downtime of the floor area. Cleanup is hassle-free as it can be done with soap and water, unlike oil-based products that require harsher solvents. Another important aspect is that this type of polyurethane is less prone to yellowing over time, ensuring that the wood retains its natural color and brightness.

For individuals with allergies or sensitivities, the reduced volatile organic compounds (VOCs) in water-based polyurethane are beneficial. It offers a balance of aesthetic appeal and practical functionality, making it an ideal choice for modern homes and environmentally conscious individuals. The Benefits of Water-Based Finishes

The Advantage of Oil-Based Polyurethane for Durable Wood Flooring

Oil-based polyurethane provides a durable and long-lasting finish for wood flooring, particularly in areas with high foot traffic. Its glossy appearance effectively resists dirt and scratches, while also offering superior water resistance and durability. This type of finish deeply penetrates the wood grain, providing extensive protection against water damage, warping, and buckling. It is especially beneficial for spaces like kitchens and bathrooms, where floors are more prone to wear and moisture. Despite its longer curing time compared to water-based alternatives, oil-based polyurethane offers unmatched longevity and protection, with the ability to safeguard wood floors for up to eight years with regular maintenance. However, it’s important to consider its flammability and higher VOC content, which can impact indoor air quality and require proper ventilation during application.

In terms of cost-effectiveness, oil-based polyurethane is often a more economical choice compared to water-based options. It requires fewer coats to achieve the same level of protection and shine, making it a practical solution for larger areas or projects with budget constraints. By reducing the number of coats needed, it not only saves time but also minimizes material costs. Additionally, the durability of oil-based polyurethane means that the need for frequent refinishing is reduced, further contributing to its cost-effectiveness.

When selecting a finish for wood flooring, it’s crucial to consider the specific requirements and conditions of the space. Oil-based polyurethane offers numerous benefits, including its ability to provide long-lasting protection against wear, moisture, and damage. Its glossy finish enhances the natural beauty of the wood, while its superior water resistance helps prevent issues such as warping or buckling. However, it’s important to be aware of its flammability and higher VOC content, which may impact indoor air quality. By weighing these factors and considering the specific needs of the project, individuals can make an informed decision on whether oil-based polyurethane is the right choice for their wood flooring. Choosing the Right Finish for Wood Floors

The Charm of Floor Wax in Wood Flooring: A Classic Finish

Floor wax, with its timeless and natural look, offers a charming, matte finish that enhances the wood grain of wood floors. It is ideal for low-traffic areas like bedrooms and living rooms. Floor wax is available in both paste and liquid forms, catering to different types of finishes. For example, paste wax is compatible with oil-based finishes, while liquid waxes work well with water-based finishes.

Applying floor wax is a relatively straightforward process, making it an excellent DIY project. It forms a protective coating over the hardwood, shielding it from scratches and scuffs. Additionally, floor wax is a budget-friendly option, making it suitable for those looking to save money. It also provides slip resistance, which is particularly beneficial in moisture-prone areas.

However, it is important to note that floor wax requires more frequent reapplication compared to other finishes. Additionally, it can be slippery when wet, posing a potential safety hazard. Moreover, meticulous cleanup is necessary, especially when removing old layers of wax, as it can be a challenging and time-consuming process. Natural Wood Finishes: Floor Wax

Exploring the Diversity of Wood Floor Finishes: From Aluminum Oxide to Penetrating Oils

When it comes to wood floor finishes, there is a wide range of options available. From highly durable finishes like aluminum oxide to the natural charm of penetrating oils and sealers, there is something for every preference. Aluminum oxide finishes are known for their extreme hardness and resistance to abrasion, making them perfect for high-traffic areas. They offer excellent protection against wear, scratches, and stains, which can save you money in the long run on maintenance and refinishing costs. These finishes come in both water-based and oil-based formulations, with water-based options being more eco-friendly due to lower VOC levels.

On the other hand, penetrating oils and sealers offer a different approach to wood floor finishes. They enhance the natural beauty of the wood by bringing out its color and grain pattern. These finishes penetrate deep into the wood, providing protection from within. They are typically easier to apply and maintain compared to surface finishes. However, it’s important to note that they may not offer the same level of protection against scratches or wear as aluminum oxide finishes. Additionally, they lack UV protection and may not be as moisture-resistant as other types of finishes.

Choosing the right wood floor finish depends on several factors, including usage, appearance, and maintenance preferences. Each type of finish has its unique advantages and considerations, so it’s crucial to select one that aligns with your specific needs and the characteristics of your wood flooring. Taking the time to research and understand the different options available can help you make an informed decision and ensure that your wood floors are protected and look their best for years to come. Guide to Wood Floor Finishes

Understanding Pre-finished Wood Floor Finishes – cutting through the marketing terms.

There are so many terms for finishes on the market. Manufacturers are trying to set their products apart, which can be confusing. Therefore, we decided to dedicate a blog post to wood flooring finishes.

There are two basic types of hardwood flooring finishes:

– Film Build finishes: These are also known as Urethane or polyurethane finishes that provide a protective layer between your feet and the wood.

– Oil or Wax finishes are finishes that permeate into the wood, fortifying each fibre, which means you’re walking directly on the wood.

Which finish is better for you?

Well, that depends on how you want to live on the floor.

Before you hire a flooring company, you should know about the pros and cons of basic finish types.

Film build – also known as Urethane/polyurethane or UV Cured Lacquer/Oil.

Pros:

These finishes require no maintenance. You don’t need to do anything except regular vacuuming to remove debris and dirt. Spot clean-up spills and if you want to “clean” at most monthly according to the manufacturer’s maintenance instructions.

Sellable Pros:

These are easy to maintain, stain and scratch/damage resistant, and non-yellowing/nontoxic. You live on the finish. The finish protects the wood from moisture and daily life damage.

Cons:

When a film build finish is damaged, you will need to hire a professional to sand off the finish, prep and re-stain. Site finishes are never as durable as a factory finish. Not all prefinished floors can be site finished; if this is important to you, tell your flooring salesperson when selecting your next hardwood flooring.

Oil/Wax

Pros:

Minor scratches or worn areas can be replenished by recoating the oil/wax. Required maintenance products are supplied with every order – no guessing on what is required.

Sellable Pros:

Repair minor wear and tear by recoating the floor.

Cons:

These floors require regular maintenance, often immediately after hardwood floor installation. You will need to move all furniture and persons from your home while you do the hardwood installation and recoating these floors.

Maintenance Products

Your oil/wax floor will come with the required maintenance and cleaning products. If they don’t, these will be easily accessible through the flooring store you purchase from. Always and only use the manufacturer’s recommended oil/wax finish cleaner and refreshers.

Your film build/urethane or cured floor has many off-the-shelf options. Look for cleaners that are specifically for urethane wood floors. Many manufacturers supply their cleaners. However, these are not typically required for your warranty on a film build or urethane floor.

NEVER use a refresher, scratch repair, sealant, or polish renew product on a film build/urethane/cured oil finished floor. The market is flooded with these products; however, they are temporary fixes that often cause more harm than good. Many of these products are acrylic based, wear quickly, and are next to impossible to remove or maintain.

Common Improper Maintenance Issues

Using the wrong maintenance product:

As seen in this photo, using an improper cleaning product on a permeable oil floor will leave a dark greasy mess/colour change. Removing and repairing the buildup with the proper products will be challenging.

Tip: ALWAYS KNOW YOUR FINISH TYPE AND THE MAINTENANCE/CLEANING PROCESS. A GOOD FLOORING RETAILER WILL REVIEW THIS WITH YOU DURING THE SELECTION PROCESS.

Cleaning with water/excess cleaner on a wired-brushed surface that is not a water-resistant finish:

As seen in both photos, moisture has penetrated under the finish through the wire-brushing, and the finish is lifting. High-quality finishes on the market have higher adhesion to wire-brushing than seen here. These types of flooring are made from natural wood. Your flooring retailer will educate you on which products have the best finishes and which products to keep far away from all sources of moisture.

Common Floor Finish Terms

Before you decide on a product for your flooring project, take flooring samples from a flooring company and determine which type of flooring is best suited for your floor. Here are some standard terms for floor finish:

Abrasion resistance refers to the wear resistance of the floor and is closely related to the service life of the flooring.

Antimicrobial flooring technology is designed to protect your hardwood floors. Advantages of antimicrobial wood flooring include: Inhibiting the growth of stain and odour-causing bacteria, allowing your hardwood floors to stay cleaner and look new for a long time.

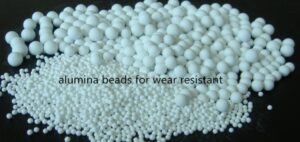

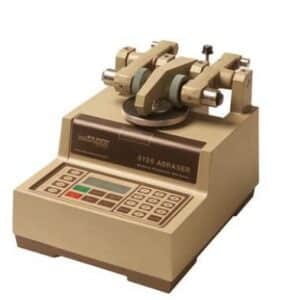

Ceramic Bead infused floor finishes commonly refer to adding Ceramic Alumina (aluminum oxide) or Ceramic Silica (silicon oxide) to create a more robust and wear-resistant finish. These finishes will also score higher on the Taber test.

The GREENGUARD Certification program offers manufacturers a standard for creating low chemical emissions or “off-gassing” in our brands’ products before our furniture enters your homes or businesses.

GREENGUARD Gold Certified standard goes beyond the regular certification to include criteria for even more chemicals. It requires lower total VOC emissions levels to ensure that products are acceptable for use in environments like schools, nurseries, and healthcare facilities.

Nanotechnology in floor finishes refers to nano-particles in UV-cured urethane floor finishes. Nanotechnology in urethane finishes can include the addition of metal or ceramic oxide such as silica in nano form.

Oil-based Polyurethane floor finishes consisting of natural oil, synthetic resins, and plasticizing solvent, and oil-based polyurethane floor finishes are incredibly durable. This finish also darkens over time, giving your high-quality hardwood flooring a warmer tone.

Oiled floors These are floors made by the process of applying oil to treat and colour the wood floor without leaving a film built. Oil-finished wood flooring options are designed to protect, stain, and add natural shine. Wood oil finishes give wood a beautiful, breathable surface.

Polyurethane finish is a liquid resin that coats wood flooring and other wood surfaces, such as cabinets and furniture. As a synthetic floor finish, polyurethane is made from raw materials derived from crude oil and, in some cases, plant-based oils. Polyurethane floor finish comes in either water-based or oil-based versions. The Novabelle Classic Engineered Hardwood Series flooring is an engineered wood product consisting of 8 coats of polyurethane and an Anti-Scratch top coat.

Taber test involves mounting a portion of a finished board onto a turntable fitted with sheets of abrasive paper. The degree of resistance is evaluated based on the number of rotations it takes to wear down the finish entirely. The higher the number of cycles, the more resistant the finish.

UV-cured Urethane is the most common type of finish for factory-finished (‘prefinished’) wood flooring. The finish is applied to the wood at the factory and then hardened via a chemical reaction triggered by ultraviolet (UV) light.

Water-based Polyurethane finishes consist of the same essential elements that make up oil-based polyurethane finishes. This finish will always retain its transparency and has a thinner consistency compared to oil-based poly, and are due not darken or yellow over time as much as an oil-based.

Waxing is a floor finishing technique in which clear or coloured wax, made of a blend of solvents and synthetic and/or natural waxes like beeswax or carnauba, is applied to a hardwood floor in a thin layer and then buffed to a shine.

Water-resistant flooring either has a fixed barrier that helps prevent moisture from gaining access into the core for some time or, in the case of wood flooring. The finish prevents damage to the wood when in the presence of excess moisture. Water resistance is a good feature however will not prevent damage from flooding or excess moisture.

Key Consideration Choosing a WOOD FLOOR FINISHES for your Home in Metro Vancouver.

Quality of Materials and Finish Options

One of the primary considerations is the quality of the materials used for wood floor finishing. Businesses that offer a range of high-quality options, including water-based and oil-based polyurethanes, wax finishes, moisture-cure urethane, and aluminum oxide coatings, should be preferred. Each of these options has its unique benefits, like durability, resistance to wear and tear, and aesthetic appeal. For instance, water-based polyurethanes are known for their eco-friendly properties and low odor, while oil-based polyurethanes are lauded for their durability and rich finish.

Environmental Considerations

In today’s eco-conscious world, the environmental impact of floor finishes is a significant concern. Options like low-VOC (Volatile Organic Compounds) finishes or natural oil treatments are increasingly popular. These not only minimize harmful emissions but also contribute to healthier indoor air quality. Businesses that prioritize eco-friendly practices and materials demonstrate a commitment to sustainability, which is a vital consideration for many homeowners.

Expertise and Experience

The expertise and experience of the business in applying various wood floor finishes are crucial. It’s essential to choose a company with a proven track record of delivering high-quality work. Experienced professionals can provide valuable insights into the most suitable finishes for different types of wood floors, considering factors like traffic, exposure to sunlight, and the overall decor of the space.

Customization and Personalization Options

The ability to customize and personalize wood floor finishes to meet specific aesthetic and functional requirements is another important consideration. Businesses that offer a range of colors, textures, and gloss levels can cater to diverse preferences, ensuring that the final result aligns with the homeowner’s vision.

Maintenance and Longevity

The long-term maintenance requirements and the longevity of the finishes are also critical factors. Some finishes, like wax, require more frequent maintenance, while others, such as polyurethane, are more durable and easier to maintain. Understanding the maintenance needs and lifespan of each option helps in making an informed decision that aligns with the homeowner’s lifestyle and maintenance preferences.

Cost and Value

While the cost is always a consideration, it’s important to balance this with the value offered. Cheaper options might save money upfront but could lead to higher maintenance costs and less durability in the long run. Conversely, more expensive options may offer better value over time due to their longevity and lower maintenance requirements.

Customer Service and Aftercare

Finally, the level of customer service and aftercare provided by the business is essential. This includes their willingness to address any concerns post-installation and their ability to provide guidance on the care and maintenance of the finished floors.

Choose Canadian Home Style for your Vancouver flooring projects.

Canadian Home Style is your family-owned and operated flooring retailer with a showroom in North Vancouver, BC. We provide full-service commercial and residential flooring solutions across the Lower Mainland with an extended warranty. We are proud members of the BC Floor Covering Association (BCFCA) and the National Wood Flooring Association (NWFA). In addition, we have won the Consumer’s Choice Awards back-to-back in 2021, 2022, 2023, and 2024 for our commitment to business excellence. We are considered the highest-rated flooring experts in Metro Vancouver. We pride ourselves on holding the highest standards in the flooring industry. To uphold our high standards, we have a strict policy of “not selling or displaying any products that we wouldn’t want in our own homes.” Before we select a product to feature, we carefully assess product quality, off-gassing, warranties, and responsible sourcing. Book now to visit our North Vancouver flooring showroom; we can help you choose the perfect floor for your home or business.

Our mission is to help homeowners create beautiful homes that reflect their lifestyles while reducing energy consumption and conserving resources. We do this by providing our clients with innovative products, services and education. Our vision is to become Canada’s leading sustainable flooring solutions provider. Our values include integrity, respect, honesty and transparency. These principles guide us as we strive to provide outstanding customer service.

We believe that our success depends on the success of our clients and their customers. We work hard to ensure our clients get the most out of their investments. Our team consists of highly skilled professionals who are experts in their field. They have years of experience working together and know what works and what doesn’t. They understand how to solve problems quickly and efficiently. We are committed to providing excellent customer service. We listen carefully to our client’s concerns and suggestions. We take these into account when planning and executing projects. We always strive to exceed expectations.

Why Choose Us?

Diverse Range of Wood Flooring Options: Canadian Home Style offers an extensive selection of wood flooring options, including both engineered wood and traditional hardwood. Engineered wood provides stability and resistance to environmental changes, making it a popular choice for many homes. Hardwood, known for its durability and timeless appeal, is available in various species, each bringing its unique aesthetic to your space.

Expert Refinishing Services: Over time, wood floors may lose their luster or suffer from wear and tear. Canadian Home Style’s refinishing services can restore the beauty of your floors. Their skilled professionals are adept at sanding, staining, and finishing wood floors to bring them back to their original glory or even give them a completely new look.

High-Quality Finishing Products: The finishes used by Canadian Home Style, including wax, varnish, and semi-gloss options, are of the highest quality. They understand the importance of using products that not only enhance the beauty of the wood but also protect it from damage and prolong its life. Their selection includes natural products for those seeking eco-friendly options.

Customizable Wood Stain Options: Personalization is key in home decor, and Canadian Home Style excels at offering customizable wood stain options. Whether you prefer a light, natural look or a darker, richer tone, they have a range of stains to suit every preference. This flexibility allows homeowners to achieve the exact aesthetic they desire for their floors.

Natural and Eco-Friendly Solutions: For those who prioritize environmental sustainability, Canadian Home Style offers natural product options. These eco-friendly solutions minimize harmful emissions and contribute to healthier indoor air quality, aligning with modern green living standards.

Do-It-Yourself Advice: Understanding that some homeowners prefer the DIY route, Canadian Home Style provides expert advice and guidance for those who choose to undertake wood floor finishing projects themselves. Their team can recommend the right products and techniques, ensuring DIY enthusiasts achieve professional-looking results.

Commitment to Quality and Customer Satisfaction: Above all, Canadian Home Style is committed to delivering top-notch quality and ensuring customer satisfaction. Their team of experts is dedicated to helping each customer find the perfect flooring solution that meets their needs, preferences, and budget.

Services We Offer:

Main Areas of Service in British Columbia: